以下配置均基于RoboMaster A板

GM6020电机控制 官方例程

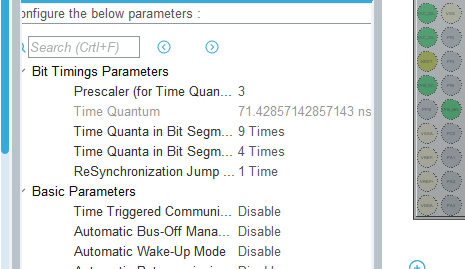

在CubeMX里面配好CAN1, 详细配置按照例程来(其实只要Time Quantum一样即可)

同时配置启用CAN1 RX0中断以便于后面处理反馈报文。另外需要按照A板的原理图,确保CAN1 TX和RX引脚为PD1和PD0

生成代码后还要按照例程加入用户初始化函数,配置过滤并启用回调函数

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 void can_user_init (CAN_HandleTypeDef* hcan) { CAN_FilterTypeDef can_filter; can_filter.FilterBank = 0 ; can_filter.FilterMode = CAN_FILTERMODE_IDMASK; can_filter.FilterScale = CAN_FILTERSCALE_32BIT; can_filter.FilterIdHigh = 0 ; can_filter.FilterIdLow = 0 ; can_filter.FilterMaskIdHigh = 0 ; can_filter.FilterMaskIdLow = 0 ; can_filter.FilterFIFOAssignment = CAN_RX_FIFO0; can_filter.FilterActivation = ENABLE; can_filter.SlaveStartFilterBank = 14 ; HAL_CAN_ConfigFilter(hcan, &can_filter); HAL_CAN_Start(hcan); HAL_CAN_ActivateNotification(hcan, CAN_IT_RX_FIFO0_MSG_PENDING); } void HAL_CAN_RxFifo0MsgPendingCallback (CAN_HandleTypeDef *hcan) { if (hcan->Instance == CAN1){ } }

[GM6020的说明书](https://rm-static.djicdn.com/tem/17348/RoboMaster GM6020直流无刷电机使用说明.pdf) 说的电机反馈格式不够明确,机械角度为unsigned short而转速和电流应该为signed short. 并且三者都是反STM32的大端模式,需要转换。

这里为了兼容C620电调给多了一个参数offset,这里只要M6020_ID_OFFSET即0x204即可

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 HAL_StatusTypeDef get_motor_data (CAN_HandleTypeDef* hcan,uint32_t offset) { CAN_RxHeaderTypeDef rx_header; uint32_t motor_id=0 ; uint8_t rx_buffer[8 ]; if (HAL_CAN_GetRxMessage(hcan, CAN_RX_FIFO0, &rx_header, rx_buffer)==HAL_OK){ motor_id = rx_header.StdId - offset; if (motor_id > 0 && ((offset == C620_ID_OFFSET && motor_id <= C620_MOTOR_NUM)|| (offset == M6020_ID_OFFSET && motor_id <= M6020_MOTOR_NUM))){ mRxMsg.raw_angle = ((rx_buffer[0 ] << 8 ) | rx_buffer[1 ]); mRxMsg.speed_rpm = ((rx_buffer[2 ] << 8 ) | rx_buffer[3 ]); mRxMsg.current = ((rx_buffer[4 ] << 8 ) | rx_buffer[5 ]); mRxMsg.tempture = rx_buffer[6 ]; } }else return HAL_ERROR; return HAL_OK; }

发送报文也需要做大小端转换,其实就是将前6个字节两两互换,id按照说明书里面的标识符选。此处可以使用Cortex-M4指令集里面的__REV16优化操作,单个指令即可完成两个16bit short的大小端转换

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 HAL_StatusTypeDef set_motor_voltage (CAN_HandleTypeDef* hcan,MotorReceiveMsg* TxMsg, uint32_t id) { CAN_TxHeaderTypeDef tx_header; uint8_t tx_buffer[8 ]; uint32_t * pTxMsg = (uint32_t *)TxMsg; *(uint32_t *)(&tx_buffer[0 ])=__REV16(pTxMsg[0 ]); *(uint32_t *)(&tx_buffer[4 ])=__REV16(pTxMsg[1 ]); tx_header.DLC=8 ; tx_header.IDE = CAN_ID_STD; tx_header.RTR = CAN_RTR_DATA; tx_header.StdId = id; return HAL_CAN_AddTxMessage(hcan, &tx_header, tx_buffer,(uint32_t *)CAN_TX_MAILBOX0); }

完成了上面收发函数后,可以采用PID控制电机转到指定角度并保持稳定。首先关于角度差值的问题,电机转向的时候有两个方向可以选,我们希望它转过小一点的那个角度。实现的逻辑是,以180度角为分界线,大于这个角度的差值的应该朝反方向转(即加/减去360)。另外直接用PID控制角度效果不佳,采用串级PID(角度+转速)可以解决这个问题,最后发送报文时还需要确保输出值在给定的-30000~30000之间

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 void set_6020_angle (CAN_HandleTypeDef* hcan, uint16_t ang, pid_struct_t pPID[2 ]) { __HAL_CAN_DISABLE_IT(hcan,CAN_IT_RX_FIFO0_MSG_PENDING); float delta_ang = ang- mRxMsg.raw_angle*360 /8192 ; int32_t current_speed = mRxMsg.speed_rpm; __HAL_CAN_ENABLE_IT(hcan,CAN_IT_RX_FIFO0_MSG_PENDING); if (delta_ang > 360 && delta_ang < -360 ) return ; if (delta_ang > 180 ){ delta_ang = delta_ang - 360 ; }else if (delta_ang < -180 ){ delta_ang = delta_ang + 360 ; } MotorReceiveMsg mMsg; memset (&mMsg,sizeof (MotorReceiveMsg),0 ); mMsg.D1 = (int32_t )pid_calc(&pPID[0 ],pid_calc(&pPID[1 ],delta_ang,0 ),current_speed); if (mMsg.D1 > 30000 ) mMsg.D1=30000 ; else if (mMsg.D1 < -30000 ) mMsg.D1=-30000 ; set_motor_voltage(hcan,&mMsg,M6020_ID_BASE); }

PID的实现可以直接拿例程里面的pid.c和pid.h,目前测试上还可以的参数pPID[0]:KP=40, KI=3, KD=0,pPID[1]:KP=30, KI=0, KD=1

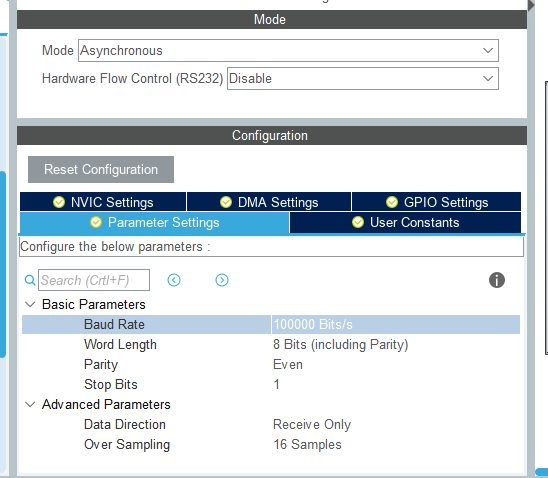

DR16遥控机接收 按照文档给的参数100000Bit/s,数据长度8位,偶校验+一位停止位配好串口。打开串口全局中断和串口接收DMA,设置DMA为循环模式

CubeMX配置好后串口无法接收数据,参见CubeMX 串口DMA无法启动

参考遥控器用户手册附录上的代码中双缓冲区的设计,在HAL库环境下同样可以利用循环DMA实现。两帧数据传输时间间隔较长,使用串口的空闲中断可以在帧结束处及时处理数据,而同时后半段缓冲区仍然能接收数据。实际上由于处理数据的时间远小于发送间隔14ms(这对于F4来说可是相当长的一段时间),单个缓冲区也可以满足要求。但是为了确保在添加其他用中断实现功能时不会干扰接收,可以选择增加1倍的缓冲区换取更宽裕的时间处理其他中断。

参照例程 写出自定义的串口DMA初始化函数,可以避免打开DMA自身中断以及全局变量传参不便的问题。其中RC_FRAME_LENGTH为帧长即18,RC_data_buffer为2倍帧长的缓冲区。

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 HAL_StatusTypeDef rc_recv_dma_init (UART_HandleTypeDef* huart) { uint32_t state = huart->RxState; if (state == HAL_UART_STATE_READY){ __HAL_LOCK(huart); huart->pRxBuffPtr = (uint8_t *)RC_data_buffer; huart->RxXferSize = 2 *RC_FRAME_LENGTH; huart->ErrorCode = HAL_UART_ERROR_NONE; HAL_DMA_Start(huart->hdmarx, (uint32_t )&huart->Instance->DR, (uint32_t )RC_data_buffer, 2 *RC_FRAME_LENGTH); SET_BIT(huart->Instance->CR3, USART_CR3_DMAR); __HAL_UART_CLEAR_OREFLAG(huart); __HAL_UART_CLEAR_IDLEFLAG(huart); __HAL_UNLOCK(huart); return HAL_OK; }else { return HAL_BUSY; } }

接下来可以照搬上面例程数据处理的函数,再在串口空闲中断(stm32f4xx_it.c中的USART1_IRQHandler)中调用

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 void parse_RC_data (uint8_t * pData) { RC_CtrlData.rc.ch0 = (int16_t )((int16_t )pData[0 ] | ((int16_t )pData[1 ] << 8 )) & 0x07FF ; RC_CtrlData.rc.ch1 = (int16_t )(((int16_t )pData[1 ] >> 3 ) | ((int16_t )pData[2 ] << 5 )) & 0x07FF ; RC_CtrlData.rc.ch2 = (int16_t )(((int16_t )pData[2 ] >> 6 ) | ((int16_t )pData[3 ] << 2 ) | ((int16_t )pData[4 ] << 10 )) & 0x07FF ; RC_CtrlData.rc.ch3 = (int16_t )(((int16_t )pData[4 ] >> 1 ) | ((int16_t )pData[5 ]<<7 )) & 0x07FF ; RC_CtrlData.rc.s1 = (uint8_t )((uint8_t )(pData[5 ] >> 4 ) & 0x0C ) >> 2 ; RC_CtrlData.rc.s2 = (uint8_t )((uint8_t )(pData[5 ] >> 4 ) & 0x03 ); RC_CtrlData.mouse.x = (int16_t )((int16_t )pData[6 ]) | ((int16_t )pData[7 ] << 8 ); RC_CtrlData.mouse.y = (int16_t )((int16_t )pData[8 ]) | ((int16_t )pData[9 ] << 8 ); RC_CtrlData.mouse.z = (int16_t )((int16_t )pData[10 ]) | ((int16_t )pData[11 ] << 8 ); RC_CtrlData.mouse.press_left = (uint8_t )pData[12 ]; RC_CtrlData.mouse.press_right = (uint8_t )pData[13 ]; RC_CtrlData.keyboard.keycode = ((uint16_t )pData[14 ]); RC_CtrlData.rc.ch0-=0x400 ; RC_CtrlData.rc.ch1-=0x400 ; RC_CtrlData.rc.ch2-=0x400 ; RC_CtrlData.rc.ch3-=0x400 ; } void UART_RxIdleCallback (UART_HandleTypeDef *huart) { if (huart->Instance == USART1 && __HAL_UART_GET_FLAG(huart,UART_FLAG_IDLE)){ __HAL_UART_CLEAR_IDLEFLAG(huart); DMA_Stream_TypeDef* uhdma = huart->hdmarx->Instance; receive_size = (int32_t )(2 *RC_FRAME_LENGTH - uhdma->NDTR) - frame_offset; if (receive_size == RC_FRAME_LENGTH || receive_size == -RC_FRAME_LENGTH){ parse_RC_data(&RC_data_buffer[frame_offset]); frame_offset = (int32_t )(frame_offset == 0 )*RC_FRAME_LENGTH; }else { __HAL_DMA_DISABLE(huart->hdmarx); uhdma->M0AR = (uint32_t )RC_data_buffer; uhdma->NDTR = (uint32_t )(RC_FRAME_LENGTH*2 ); frame_offset=0 ; __HAL_DMA_ENABLE(huart->hdmarx); } } }

其中为了防止开始时接收到半帧(偶然情况)而导致帧开始不在缓冲区开头或中间,加入错误处理,如果发现数据长度有误则重启DMA接收。单缓冲区的错误处理也同理。摇杆的零位对应ch0~ch3的中间值1024,减去1024可以让正负符号代表方向便于处理。